Welcome to Guilin HCM Machinery Official WebSite!

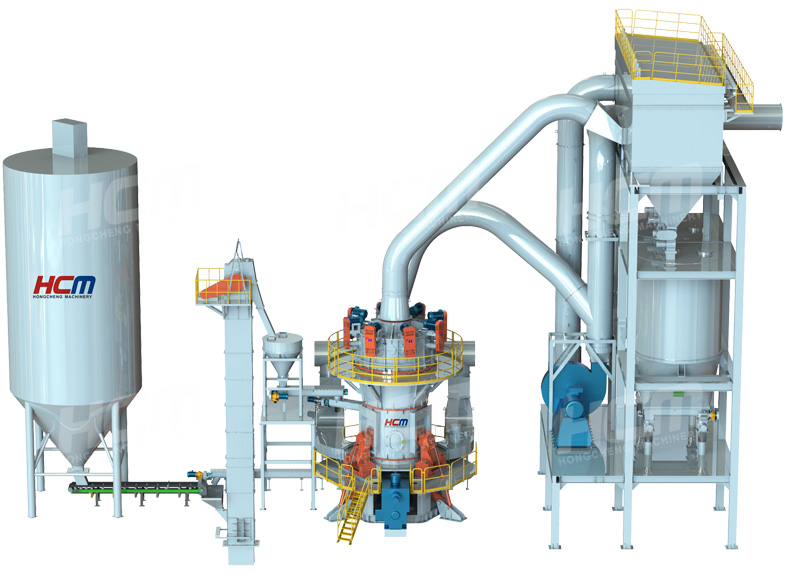

HLMX series ultra-fine vertical mill is a large ultra-fine vertical mill developed by Guilin Hongcheng on the basis of HLM vertical mill by referring to the technology of Germany, Japan and Taiwan, which is suitable for the development of non-metallic mineral industry. Among them, the HLMX1700 ultra-fine vertical mill is currently the super-large ultra-fine grinding equipment in Asia, which has been successfully applied in the market and has mature technology. It can replace imported equipment and is an ideal equipment for large-scale production of ultrafine powder with high efficiency, high yield, environmental protection and energy saving.

It is suitable for superfine grinding of non-metallic minerals such as calcium carbonate superfine powder, limestone, barite, calcite, kaolin, gypsum, pyrophyllite and graphite. It can provide high-quality fillers and additives for industries such as papermaking, plastics, coatings, rubber inks, and chemicals.

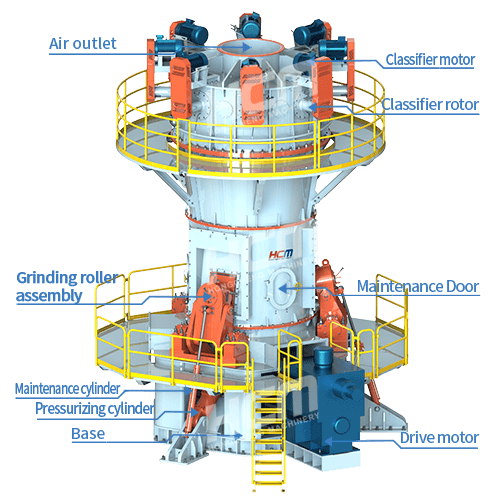

The roller sleeve and liner grinding curve specially designed for ultra-fine powder grinding makes it easier to form a material layer, with high grinding efficiency and high yield of one-time grinding.

It adopts PLC automatic control system and can realize remote control, which is easy to operate, easy to maintain and reduce labor costs.

The production capacity of a single machine is large, and the output is as high as 50t/h, which is equivalent to more than 5 micro-powder mills. It can save energy by 30-50% compared with ordinary mills to produce products with the same fineness.

The material stays in the mill for a short time, reducing repeated grinding, and the finished product has less iron content, high whiteness and purity, uniform particle shape, narrow particle size distribution, small cut point, good fluidity and strong adaptability.

The grinding roller can be turned out of the machine by hydraulic device, which is convenient for maintenance. Grinding roller sleeves can be turned over for use, prolonging the service life of wear-resistant materials, with low wear and tear. Grinding rollers and grinding disc liners are made of special materials, with long service life.

The grinding roller limit device is adopted to avoid the severe vibration of the mill due to material breaking. Adopting a new grinding roller sealing device, the sealing is reliable, and there is no need for a sealing fan, which further reduces the oxygen content in the grinding mill and has excellent explosion suppression performance.

The whole system has small vibration and low noise. It adopts an overall sealed negative pressure operation system and an air box pulse dust removal system. There is no dust spillage, and a dust-free workshop can basically be realized.

Integrating crushing, drying, grinding, grading, and conveying, the process flow is simple, the structure layout is compact, and the floor space is small, only 50% of the ball mill. It can be arranged in the open air, the construction cost is low, and the investment cost is directly reduced.

| Model | Grinding Table Diameter(mm) | MaxFeedingSize(mm) | Material Moisture(%) | Fineness | Capacity(t/h) | Power(KW) |

| HLMX600 | 600 | <10 | ≤5 | 7-22um Finest reachable 3um(Equipped with secondary classification system) | 1-6 | 55 |

| HLMX880 | 880 | 2-8 | 160 | |||

| HLMX1000 | 1000 | 3-12 | 200 | |||

| HLMX1100 | 1100 | 4-14 | 250 | |||

| HLMX1300 | 1300 | 5-16 | 280 | |||

| HLMX1500 | 1500 | 7-18 | 355 | |||

| HLMX1700 | 1700 | 8-20 | 500 | |||

| HLMX2000 | 2000 | 10-25 | 560 | |||

| HLMX2400 | 2400 | 20-40 | 800 | |||

| HLMX2600 | 2600 | 25-45 | 1400 | |||

| HLMX2800 | 2800 | 30-50 | 1800 |

| Capacity(t/h) | 18-20 | 12-15 | 10-12 | 7-9 | 5.5-6 | 2-3.5 | 1.5-2 |

| Specific surface area(cm²/g) | 16000±500 | 16000±500 | 18000±500 | 18000±500 | 21000±500 | 23000±500 | 26000±500 |

| 325 mesh residual amount(%) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Less than 2μm content(%) | 24±2 | 34±2 | 36±2 | 43±2 | 50±2 | 60±2 | 80±2 |

| cumulative weight d50 particle size(μm) | 5.3 | 2.7 | 2.5 | 2.4 | 1.8 | 1.5 | 0.8 |

| cumulative weight d97 particle size(μm) | 22 | 15 | 12 | 10 | 8 | 5 | 3 |

| Maximum particle size cut point(μm) | 24 | 24 | 16 | 16 | 24 | 24 | 24 |

| true specific gravity(t/m3) | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 | 2.7 |

| false specific gravity(g/cm3) | 0.94 | 0.94 | 0.85 | 0.85 | 0.94 | 0.94 | 0.94 |

| Whiteness | >98 | >98 | >98 | >98 | >98 | >99 | >99 |

| Moisture(%) | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 |

| PH value | 9.5±0.5 | 9.5±0.5 | 9.5±0.5 | 9.5±0.5 | 9.5±0.5 | 9.5±0.5 | 9.5±0.5 |

| Loss on ignition | 43.4 | 43.4 | 43.4 | 43.4 | 43.4 | 43.4 | 43.4 |

| SiO2 content(%) | <0.2 | <0.2 | <0.2 | <0.2 | <0.2 | <0.2 | <0.2 |

| Fe content(%) | <0.02 | <0.02 | <0.02 | <0.02 | <0.02 | <0.02 | <0.02 |

| CaCO3 (%) | >95 | >95 | >95 | >95 | >95 | >95 | >95 |

| Settled volume after 1 hour (c.c) | 34 | 34 | 42 | 42 | 50 | 60 | 70 |

| Dop Absorption capacity (c.c/100g) | It is related to the downstream use of the product and the addition of additives | ||||||

| testing method |

1.Particle size distribution: Measured by Micro laser winding particle size analyzer of British MALVERN company. 2.Average particle size: The median value of the particle size is obtained from the particle size distribution. 3.Specific surface area: converted from the average particle size, the relative area of 1g powder. 4.325-mesh residue: filter 1000g of the sample on a 325-mesh sieve by wet method, and calculate the percentage. 5.False specific gravity: Put a 50g sample in a 100c.c graduated cylinder and drop it 150 times from a height of 5cm. 6.Whiteness: Compared with the whiteness of Mg0 (Mg0=100%), it is measured by Nissan c-300-3 whiteness. 7.Moisture: JIS-K5101 100°C for 2 hours. 8.PH value: Measured with C231 PH value meter produced by Italian CONSORT company. 9.Ignition loss: the loss of burning the sample at 1000℃ for 1 hour. 10.Sedimentation volume: Put 15g sample into a 100c.c measuring cylinder with plug, add water to 100c.c and shake vigorously, let it stand still for 1 hour, then measure its sedimentation volume (at 20°C). 11.Oil absorption: drop 100g sample and add linseed oil to titrate to saturation. |

||||||

It is composed of ultra-fine classifier, fan, dust collector, silo, screw conveyor, pipeline and other equipment. Configure the classification system of secondary air separation. The classifier and fan are controlled by frequency conversion and speed regulation, with high powder separation efficiency; It adopts single-head and multi-head powder concentrators to effectively control the fineness of finished products. The finished product has a wide range of fineness, from 3um to 22um, and can efficiently obtain qualified products of various specifications.