Welcome to Guilin HCM Machinery Official WebSite!

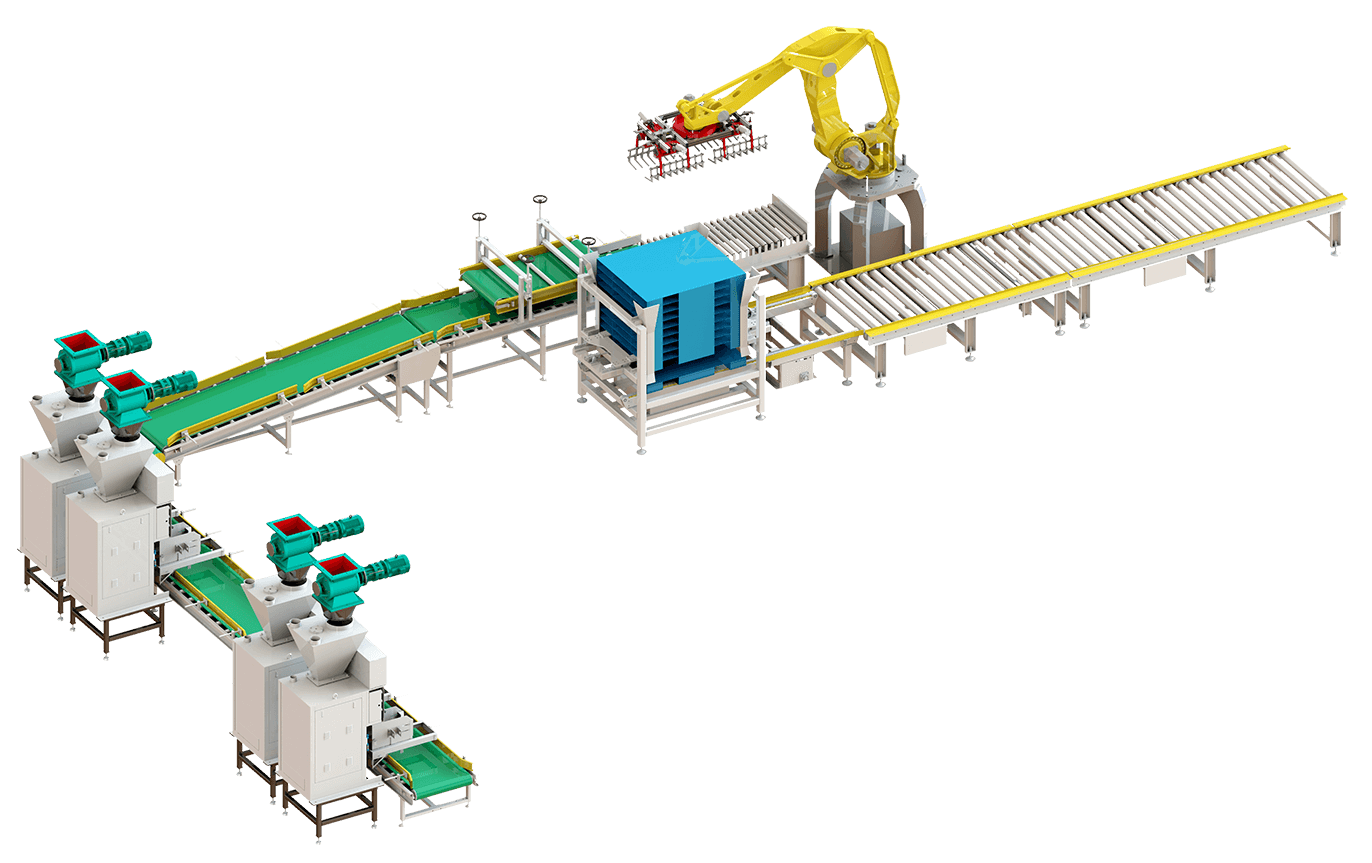

It adopts the production line of automatic stacking by robots. Through computer program control, it can realize automatic packaging, bagging, conveying, shaping, adjustment, stacking, stacking and other functions. At the same time, personalized design can be made according to customer product and process requirements. The production process is characterized by small labor force, space saving, flexible and accurate operation, fast and efficient. It is widely used in the milling, storage and transportation of electric power, metallurgy, cement, chemical industry, non-metallic minerals and other industries, such as talc powder, barite, calcite, kaolin, titanium dioxide, limestone, bentonite, iron ore, etc.

High production efficiency and wide application range.

Equipped with the whole stacking device, the stacking is neat and clean.

High degree of automation, saving labor costs.

Low operating power and energy saving.

Stable performance and low maintenance cost.

Wide screen full color human-machine interface, easy to operate.

| Model | Packing weight | Palletizing efficiency | Fineness range | Power supply | Installed power | Compressed air source | Equipment floor space |

| MD5 | 20~50kg/bag | Single grab 15t/h(25kg/bag) Double grab 22t/h(25kg/bag) | 325~2500 mesh | AC380V×3Φ 50Hz including zero line and ground wire | 92KW | ≥0.6MPa 10NL/min | 15m*3m*4m |

Fineness:22-180μm

Capacity:5-700t/h

Fineness:3-45μm

Capacity:4-40t/h

Fineness:38-180μm

Capacity:1-90t/h

Fineness:38-180μm

Capacity:1-35t/h

Fineness:38-180μm

Capacity:0.3-20t/h

Fineness:5-38μm

Capacity:1-11t/h