Welcome to Guilin HCM Machinery Official WebSite!

Fine classifier is a new generation of high-efficiency classifying equipment independently developed by Guilin Hongcheng. It mainly includes LFX series classifiers and FW series classifiers, covering powder classifying functions from 80 mesh D97 to 3000 mesh D97. The whole system has fast material flow, high classification accuracy, convenient cutting particle size adjustment, low comprehensive investment cost and good environmental protection performance. It can meet the diversified use of products, improve the overall value of products, and is applicable in a wide range of fields.

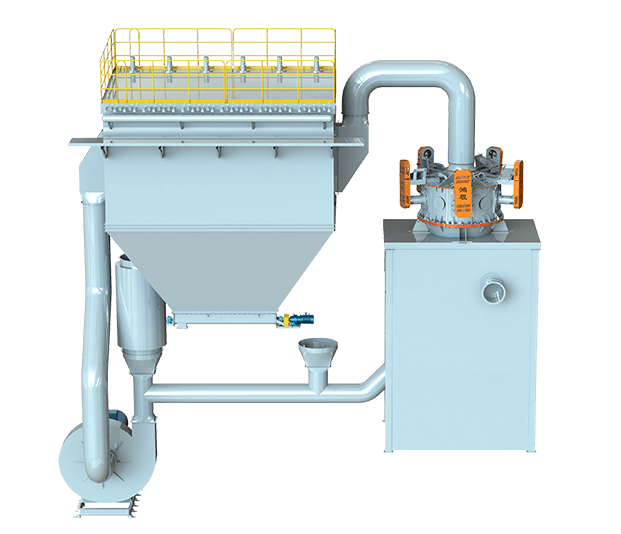

Open Circuit System: The material enters into the feeding pipe quantitatively through the feeder, and enters into the classifier through the lower feeding port after being mixed with the system air inlet evenly. Fine particles meeting the particle size requirements enter the pulse collector with the air flow, and some fine particles entrained by coarse particles fall down to the secondary air along the silo wall. The coarse and fine particles are classified by the elutriation of secondary air. The fine particles rise to the classification area for secondary classification, and the coarse particles fall to the discharge port for discharge.

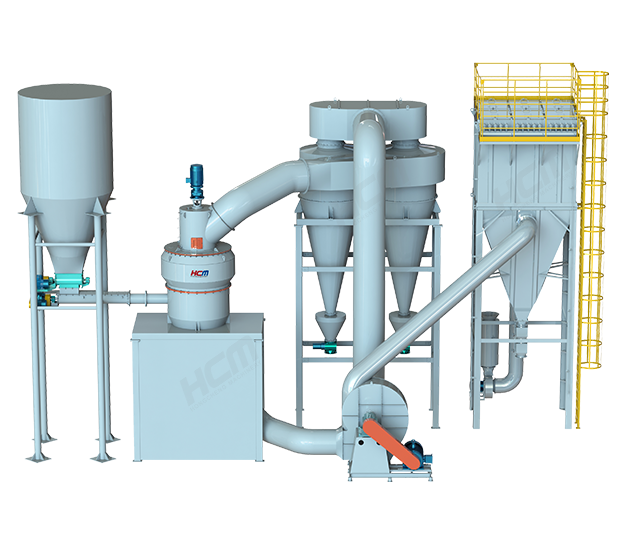

Closed Circuit System:The material enters into the feeding pipe quantitatively through the feeder, and enters into the classifier through the lower feeding port after being mixed with the system air inlet evenly. The fine particles meeting the particle size requirements enter the cyclone collector with the air flow, and the air flow after collecting the fine powder returns to the classifier again, forming a closed circuit. A part of the circulating air flow enters the residual air pulse and is discharged after dust removal. The coarse particles with some fine particles fall down to the secondary air along the silo wall, and the coarse and fine particles are separated by the elutriation of the secondary air. The fine particles rise to the classification area for secondary classification, and the coarse particles fall to the discharge port for discharge.

| Model | Fineness | Capacity(t/h) | Power(kW) |

| LFX315-1 | 5-22μmD97 | 0.64-1.12 | 22 |

| LFX315-3 | 1.92-3.36 | 3×22 | |

| LFX315-6 | 3.84-6.72 | 6×22 | |

| LFX500-1 | 1.6-2.8 | 30 | |

| LFX500-3 | 4.8-8.4 | 3×30 | |

| LFX500-5 | 4.8-14 | 3×30 | |

| LFX500-6 | 9.6-16.8 | 6×30 | |

| LFX500-8 | 12.8-22.4 | 8×30 | |

| LFX630-1 | 2.6-4.55 | 45 | |

| LFX630-3 | 7.8-13.65 | 3×45 | |

| LFX630-5 | 13-22.75 | 5×45 | |

| LFX630-6 | 15.6-27.3 | 6×45 | |

| LFX630-8 | 20.8-36.4 | 8×45 | |

| LFX800-1 | 4.2-7.35 | 75 | |

| LFX800-3 | 12.6-22.05 | 3×75 | |

| LFX800-5 | 21-36.75 | 5×75 | |

| LFX800-6 | 25.2-44.1 | 6×75 | |

| LFX800-8 | 33.6-58.8 | 8×75 | |

| LFX1000-1 | 6.8-11.9 | 132 | |

| LFX1000-3 | 20.4-35.7 | 3×132 | |

| LFX1000-5 | 34-59.5 | 5×132 | |

| LFX1000-6 | 40.8-71.4 | 6×132 | |

| LFX1000-8 | 54.4-95.2 | 8×132 | |

| LFX1250-1 | 10.6-18.55 | 200 | |

| LFX1250-3 | 31.8-55.65 | 3×200 | |

| LFX1250-5 | 53-92.75 | 5×200 | |

| LFX1250-6 | 63.6-111.3 | 6×200 | |

| LFX1250-8 | 84.8-148.4 | 8×200 |

| Model | Fineness | Capacity(t/h) | Power(kW) |

| FW500 | 22-180μmD97 | 3.5-5 | 4-7.5 |

| FW630 | 7-9 | 7.5-15 | |

| FW800 | 12-15.5 | 15-30 | |

| FW1000 | 17.2-22 | 22-45 | |

| FW1200 | 22-28.5 | 30-55 | |

| FW1300 | 28-36 | 37-75 | |

| FW1500 | 35-45 | 45-90 | |

| FW1800 | 56-72 | 55-110 | |

| FW2000 | 66.5-85.5 | 75-132 | |

| FW2300 | 87.5-112.5 | 90-160 | |

| FW2800 | 115.5-148.5 | 110-220 | |

| FW3150 | 147-189 | 160-315 | |

| FW3550 | 185.5-238.5 | 200-400 |

Fineness:22-180μm

Capacity:5-700t/h

Fineness:3-45μm

Capacity:4-40t/h

Fineness:38-180μm

Capacity:1-90t/h

Fineness:38-180μm

Capacity:1-35t/h

Fineness:38-180μm

Capacity:0.3-20t/h

Fineness:5-38μm

Capacity:1-11t/h