Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2021-06-11 15:37:32

Which is cheaper, phosphorous slag powder or silica fume? What aspects can phosphorous slag powder and silica fume be applied to? What is the price of phosphorous slag powder and silica fume grinding mill? To find out which is cheaper for phosphorous slag powder and silica fume, we need to know what difference the two have in composition, downstream products and processing technology.

.jpg)

What are the main components of phosphorus slag powder and silica fume?

Phosphorus slag powder exists in the form of silicate glass, and its main composition is SiO2Al2O3 fe2o3mgo Cao Nao. Silica fume is also called micro silica powder, or micro silica powder or ultra-fine silica powder, generally referred to as silica fume. Silica fume is a kind of ultra-fine silicon powder material, which is formed by the rapid oxidation and condensation of SiO2 and Si gas produced in smelting ferrosilicon and industrial silicon with oxygen in the air.

What is the difference between phosphorous slag powder and silica fume?

Phosphorus slag powder is widely used in cement industry and concrete industry. It can be used as recycled aggregate and filler to slow down the flexural and compressive strength of cement.

Silica fume is usually used as filler for interstitial pore of cement particles, and can also be made into gel in cement concrete, mortar and refractories.

Which is cheaper, phosphorous slag powder or silica fume?

After understanding the upstream and downstream products of phosphorous slag powder and silica fume, the price difference between phosphorous slag powder and silica fume is analyzed. According to the purchase platform, phosphorous slag powder is 160 ~ 580 yuan / ton, and silica fume is 140 ~ 900 yuan / ton. Another important factor is the difference between the two pulverizing equipment. A good grinding mill not only has great difference in energy consumption, but also in the quality of phosphorus slag powder and silica fume products.

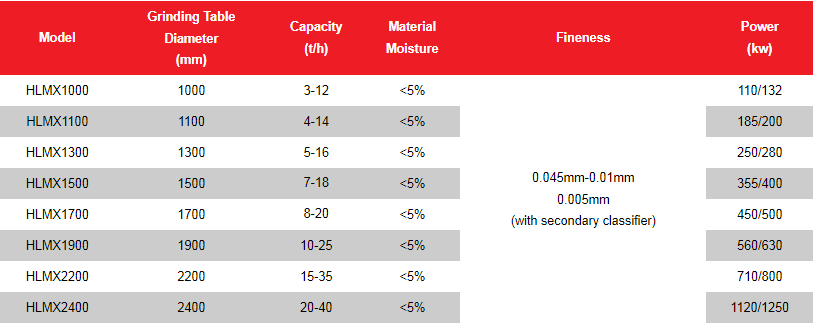

HCM production of super-fine vertical grinding mill, learn from Germany, Japan, Taiwan technology. It integrates crushing, drying, grinding and conveying. It breaks through the bottleneck of high fine powder processing capacity, can replace imported equipment, and become the ideal equipment for large-scale production of high fine powder. In the production of products with the same fineness grade, it can save 30% - 50% energy compared with ordinary mills, which is more effective.

It has the advantages of simple technological process, less system equipment, compact structure and small floor area, which is only 50% of the ball mill. Product fineness 3-45 μ M can be adjusted at will, the model 1-40t / h can be customized at will.

If you are in need of any non-metallic grinding mill, contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.