Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2021-07-06 11:50:54

Recently, with the price of titanium dioxide rising gradually, many people began to ask how to deal with the waste of titanium dioxide factory? HCMilling(Guilin Hongcheng) will share the waste treatment methods of titanium dioxide plant with you below!

What is the waste of titanium dioxide factory?

The waste of titanium dioxide plant mainly includes solid, gas and liquid. This time, we mainly talk about the solid waste in the waste of titanium dioxide plant. The waste of titanium dioxide plant contains calcium, iron, sulfur and other chemical components, and the main by-product is gypsum.

If the waste of titanium dioxide plant is directly stacked or landfilled, it will bring a certain degree of damage to the environment and endanger animals, plants and human beings.

How to deal with the waste of titanium dioxide plant?

There are three ways to deal with the waste of titanium dioxide plant

(1) The waste of titanium dioxide plant contains titanium dioxide dry base ≤ 40%, which can be treated by flotation, and then enter the sewage treatment station for treatment.

(2) The dry basis content of titanium dioxide waste is less than or equal to 50% and more than 40%. It can be acidolysed separately, ground and powdered to produce low-grade products.

(3) The dry basis of the waste material of titanium dioxide plant is more than 50%, which can be grinded again by adding mineral powder to make white gypsum for cement production, and the Yellowstone paste can also be produced. After drying, part of it can be used for brick making project and auxiliary materials for cement production.

(4) The waste of titanium dioxide plant, through selection, primary crushing, grinding and other processes, produces thin-walled brick, which has greatly improved strength and stability, light weight, high strength, high safety, and good sound and heat insulation effect.

What kind of grinding and crushing equipment to deal with the waste of titanium dioxide plant?

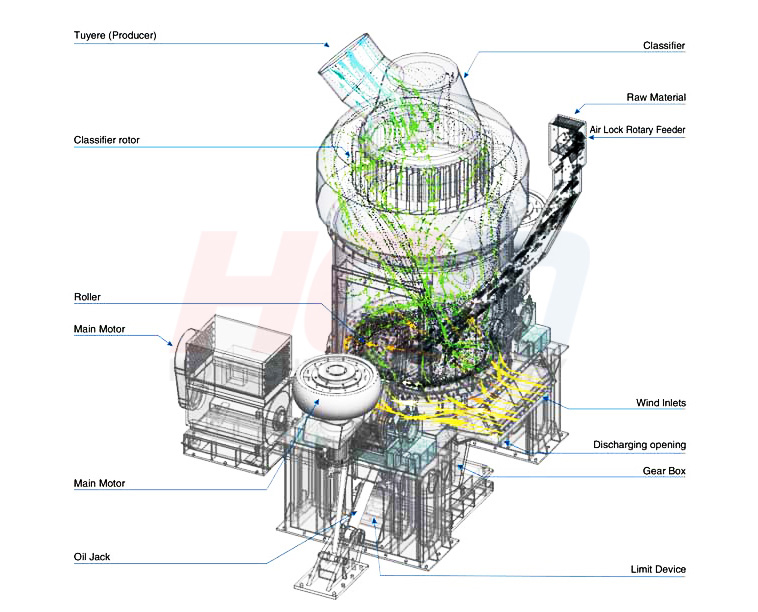

The waste of titanium dioxide plant belongs to one kind of solid waste. HCM vertical roller mill has been used for solid waste treatment for nearly 20 years, and the equipment has introduced foreign advanced technology. It is a set of crushing, drying, grinding, classification, transportation as one of the advanced grinding equipment with high efficiency and energy saving.

HLM series vertical roller mill:

*Disc diameter*:1000-52400mm

*Moisture content of feed material*:≤5%

*Capacity *:4-40t/h

*Product fineness*:10-45 μ The secondary classification of m-match can reach 5 μ m

*Application filed*:It is widely used in papermaking, coating, plastics, rubber, pigment, ink, PVC and other fields of production and life.

*Applicable materials*:It has high capacity and high efficiency for grinding of various nonmetallic mineral materials with Morse hardness below 7 and humidity less than 6%. For example, limestone, calcite, marble, heavy calcium, kaolin, barite, bentonite, pyrophyllite and other grinding effects are good.

.jpg)

HCMilling(Guilin Hongcheng) is a mine equipment R & D and production manufacturer with 30 years of experience. The company's main Raymond mill, vertical roller mill, super-fine vertical grinding mill, ultrafine mill and other ore grinding equipment. Over the past 30 years, we always stick to our original intention and serve every customer with integrity.

If you are in need of any non-metallic grinding mill, contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.