Welcome to Guilin HCM Machinery Official WebSite!

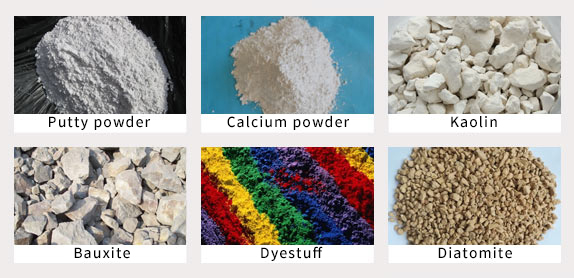

FKO1 automatic quantitative ordinary valve port packaging machine is a new type of high-precision powder quantitative packaging machine. Its structure is simple and reasonable. It is composed of centrifugal powder throwing mechanism, powder feeding control mechanism, weighing mechanism, bag clamping unit and pneumatic unit. It adopts imported chip electronic weighing system and PLC control to realize one-key operation. The equipment has high, medium and low three-stage feeding speed to ensure metering accuracy. At the end of packaging, automatically push the bag, drop the bag and stop the machine. It has fast packaging speed, high precision, energy saving and environmental protection. It can be used for the packaging of putty powder, calcium powder, kaolin, bauxite, dye, diatomite, silica fume and other powder materials.

The company's third-generation packaging machine products. The whole machine is simple, the packaging efficiency is high, the degree of automation is high, and the maintenance cost is low.

Imported chip electronic weighing system, fully automatic microcomputer control, high weighing accuracy.

All electrical components are installed in dustproof sealed type, with good dustproof performance and stable and reliable performance.

Equipped with dust removal module, the dust raised during packaging is small.

It can be equipped with automatic package unloading module and form an automatic packaging and stacking production line with robot stacking line.

| Model | Packing weight | Packaging efficiency | Packaging accuracy | Measurement method | Fineness range | Power supply | Installed power | Compressed air source | Valve bag |

| FK01 | 15~50kg | 4~5t/h | ±0.2kg/bag | Total payload | 200~2500mesh | AC380V×3Φ 50Hz with ground wire | 5.5KW | ≥0.6MPa 200NL/min | Applicable valve port Φ60~80mm |

Ton bag packaging machine is also called big bag packaging machine, ton bag packaging machine and ton bag packaging scale. It is a new generation of intelligent packaging products designed by our company according to different characteristics of packaging materials and different requirements of manufacturers. It can realize automatic feeding, metering, decoupling and conveying. It is a high-precision environment-friendly packaging machine integrating electronic weighing, automatic bag removal and dust removal. It adopts variable frequency stepless speed regulation, full-load metering, fast efficiency and high accuracy. It is suitable for quantitative packaging of powder, particle and block materials with good fluidity. It can be widely used in cement, chemical, feed, fertilizer, metallurgy, minerals, building materials and other industries.

Simple structure, anti-blocking material, high packaging efficiency, high degree of automation and low maintenance cost.

Touch screen display, easy to set and operate, and can be equipped with automatic printing output.

The imported chip electronic weighing system has high weighing accuracy.

All electrical components are installed in dustproof sealed type, with good dustproof performance and stable and reliable performance.

Equipped with dust removal interface, the dust emission during packaging is small.

| Model | Packing weight | Packaging efficiency | Packaging accuracy | Measurement method | Fineness range | Power supply | Installed power | Compressed air source | Valve bag |

| DP01 | 500~1500kg | 15~20t/h | ≤5‰ | Total payload | ≤1250mesh | AC380V×3Φ 50Hz with ground wire | 6.2KW | ≥0.6MPa 580NL/min | -4KPa 700NL/min |

Fineness:22-180μm

Capacity:5-700t/h

Fineness:3-45μm

Capacity:4-40t/h

Fineness:38-180μm

Capacity:1-90t/h

Fineness:38-180μm

Capacity:1-35t/h

Fineness:38-180μm

Capacity:0.3-20t/h

Fineness:5-38μm

Capacity:1-11t/h